|

|

|

INFORMATION DETAILS

ID: 33584751

|

Year: 2018

|

Make: Vaderstad

|

Model: Swift 400-870

|

Type: New

|

| MSRP:

N/A |

Engine Size - cc: N/A |

SELLER DESCRIPTION

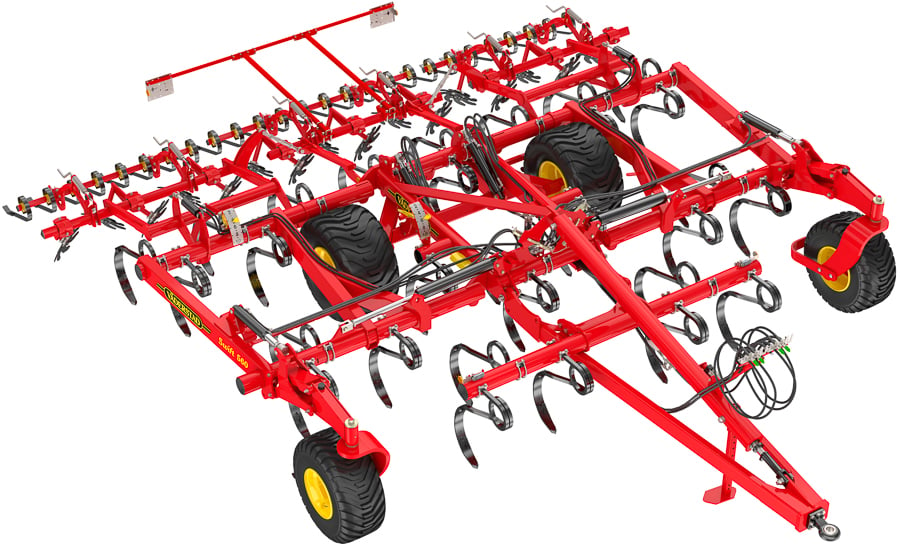

High capacity - low draught requirement

Swift is a trailed tine cultivator, designed to perform at peak level in both wet and dry years. The models in the product family span from 4.0 to 8.7 metre working width.

You benefit from a spacious design, which can handle large quantities of crop residues. The narrow tine spacing resulting in an intensive mixing and even working result.

|

|

Features

|

|

Vibrating tines Vibrating tines

The Swift tines provide effective mixing down to 20cm working depth. Since the tine vibrates with a frequency up to 100 times per second, it produces a very fine soil.

An additional benefit comes from the fact that the vibrations result in less wear on points, thereby lowering operating costs and time spent on service.

The Swift tine is unique in its strength and therefore comes with a three-year warranty.

|

Unique frame construction

Each tine axle is equipped with two tines – one in front of the axle and one behind. This construction allows for a narrow tine spacing of 19.3cm, providing intensive mixing over the entire working width.

Swift’s unique design offers a low machine weight which results in minimised draught requirement. Floating wings on the larger Swift models maintains a constant depth even in hilly conditions

|

Depth setting from cab

A large distinct scale clearly displays the working depth, which is set hydraulically from the cab on the move.

This allows the driver to adapt the working result to different soil types or varying conditions in the field.

|

Wide choice of points and shins

To meet differing farming needs, Swift can be fitted with a wide range of points and shins.

The tine is constructed as a modular system, enabling quick change and high versatility. With the right choice of points and shins you are able to optimise the working result on your fields, providing the best start possible for the next crop.

|

MixIn - Double mixing and crumbling

All Väderstad tine cultivators are equipped with the unique MixIn shin as standard.

The MixIn shin throws the material forwards instead of upwards, which otherwise is the usual direction. When it has landed, the material passes by the tines once again, and the mixing and crumbling effect is doubled. The forward movement further enhances the straw distribution, leading to a more even crop emergence.

The unique MixIn shin provide superior mixing and crumbling, without increasing fuel costs.

|

Goose foot - the ideal choice for organic farming

Equipped with goosefoot points, Swift is able to control weeds. After it has been cut by the goosefoot, the weed residues are left on the field surface to decompose.

The 240mm wide goosefoot has been designed to provide full cut-out and a long working life.

|

Levelling from the cab

Swift is equipped with levellers to ensure the field is left even after cultivation.

To be able to adapt to varying soil conditions, the driver is able to adjust the intensity of the hydraulic levellers with millimetre precision on the move.

The levellers are mounted to the machine with TriForce rubber suspension, thereby ensuring responsive contour following

|

Reconsolidation when needed

Swift can be fitted with a rear drawbar so a Rollex or Rexius roller can be attached for reconsolidation, levelling and clod crushing. |

|

Technical data

|

|

|

|

Effective working width (m) |

4,05 |

4,44 |

5,60 |

6,36 |

7,14 |

8,69 |

|

Packer width (m) |

N/A |

|

Transport width (m) |

3,0 |

3,0 |

3,0 |

3,0 |

3,0 |

3,0 |

|

Transport height (m) |

2,8 |

3,0 |

3,6 |

3,3 |

3,7 |

4,0 |

|

Weight min/max (kg) |

3000/3200 |

3100/3300 |

3500/4000 |

4500/5000 |

4600/5200 |

5100/5600 |

|

Number of tines |

21 |

23 |

29 |

33 |

37 |

45 |

|

Tine spacing (cm) |

19,3 |

19,3 |

19,3 |

19,3 |

19,3 |

19,3 |

|

Brakes |

N/A |

N/A |

H/P |

H/P |

H/P |

H/P |

|

Recommended working speed (km/h) |

10-14 |

10-14 |

10-14 |

10-14 |

10-14 |

10-14 |

|

Wheel dimension (support wheels) |

N/A |

N/A |

10,0/75-15,3 / 400/60-15,5 |

520/50-17 |

520/50-17 |

520/50-17 |

|

Wheel dimension (transport wheels) |

520/50-17 |

520/50-17 |

520/50-17 |

520/50-17 |

520/50-17 |

520/50-17 |

|

Hydraulic requirements (DA) |

3/4 |

3/4 |

3/4 |

3/4 |

3/4 |

3/4 |

|

Draught requirements from (hp) |

130 |

140 |

170 |

190 |

220 |

260 |

|

Back

|

|

|

|