|

Features

|

|

MotoGP™ DNA MotoGP™ DNA

The CBR1000RR-R Fireblade SP has been redesigned from the ground up with heavy input from the HRC MotoGP™ development program. The engine and chassis technology lean heavily on that of the RC213V-S 'Street legal MotoGP™ machine', with aerodynamics drawn from the RC213V MotoGP™ bike. The Fireblades engine, handling and aerodynamics are built for outright track performance.

|

|

Maximum power Maximum power

To help achieve the maximum power output and the required valve size, combustion efficiency and friction reduction, theRR-R SP's engine shares the same ‘over square’ 81 mm bore and 48.5 mm stroke as the RC213V-S – a radical change from the 76 x 55 mm of the previous design, and the largest bore size among current inline four-cylinder 1000 cc machines.

|

|

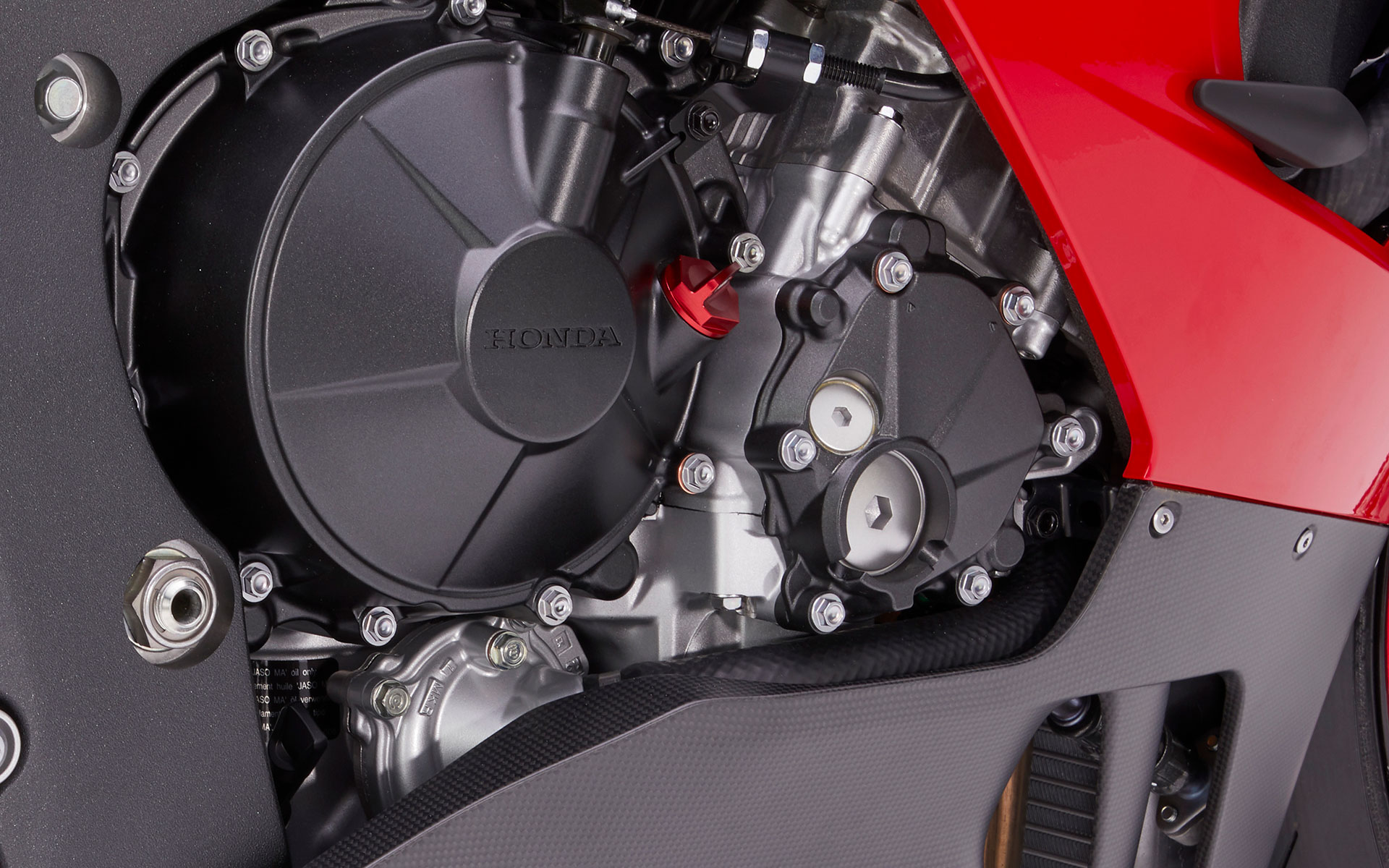

Reduced friction Reduced friction

The engines durability has been improved by reducing internal friction, the cam lobes are now coated in Diamond Like Carbon (DLC) – similar to the RC213V-S. This is the first time this process has been used on a mass-production motorcycle. The cylinders also feature a build-in bottom bypass (patent-pending) which circulates cool water from the radiator into the main water jacket, while the area below uses non-cooled water. The outcome is a lower, more even temperature at all points across the bores for less distortion and friction.

|

|

Semi-cam gear train Semi-cam gear train

The valve train is driven by a new (patent-pending) semi-cam gear train system. To drive such high-rpm/high-cam lift performance the chain is driven from the timing gear located on the crank shaft via the cam idle gear – making it shorter in length and reducing weight.

|

|

Ram-air induction Ram-air induction

A ram-air duct located in the front fairing tip feeds through the headstock, around the steering stem and into the airbox; this smooth path is made possible by the application of Honda’s Smart Key System. The area of the opening for this system is equivalent to that of the RC213V MotoGP™ machine and it's design provides high ram pressure in a stable manner at a wide range of speeds.

|

|

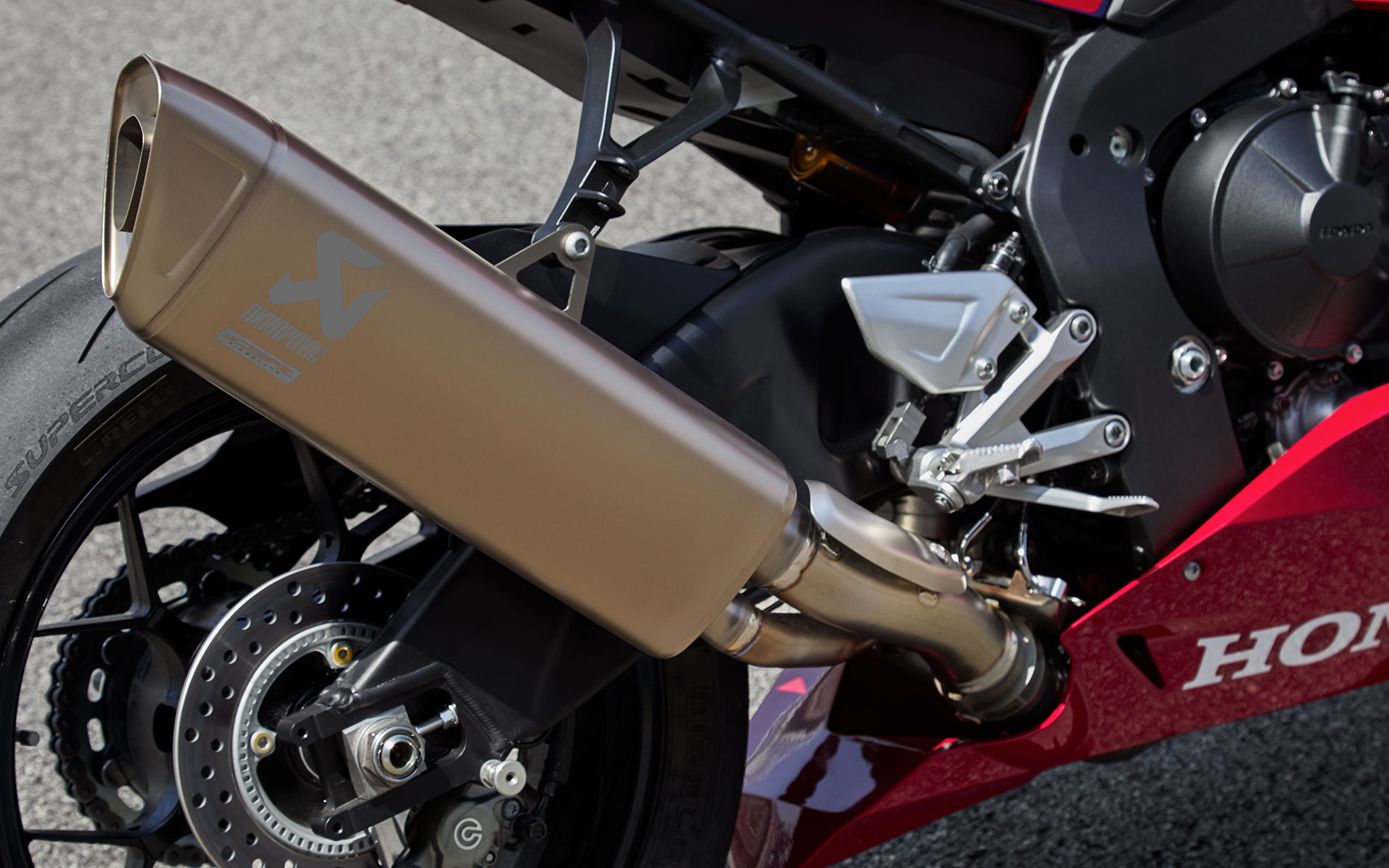

Akrapovic exhaust Akrapovic exhaust

The 4-2-1 exhaust downpipes have optimized diameters and oval cross section to improve gas flow. The smaller, lightweight titanium exhaust muffler was developed in conjunction with Akrapovic, to help deliver both low-rpm torque and high-rpm power; a valve stopper (patent-pending) helps stop exhaust-gas leak when closed while also reducing noise, allowing the mufflers total internal volume to be reduce by 38%.

|

|

Throttle by wire Throttle by wire

Throttle By Wire (TBW) has been enhanced for faster response through a range of part throttle applications - such as gradual opening as you exit a corner – minimizing any delay in torque delivery. It's derived from the RC213V-S to provide more linear delivery and puts precise throttle control - and a natural feel - in the rider's right hand.

|

|

Riding modes Riding modes

Three default riding modes feature options to change the engines output and character. Power (P), Engine Brake (EB) and Wheelie (W) control can all be adjusted within the modes.

|

|

Wheelie Control Wheelie Control

Wheelie control uses information gathered by the IMU on pitch angle, along with front and rear wheel speed sensors to maintain torque and manage any front wheel lift without sacrificing forward drive.

|

|

Honda Selectable Torque Control Honda Selectable Torque Control

Honda Selectable Torque Control (HSTC) adjusts through 9 levels and off. HSTC has been optimized for the 2020 machine and now adds slip rate control to moderate rapid wheel spin. In conjunction with the existing outright slip control, HSTC is smooth in operation while helping deliver maximum rider confidence.

|

|

Start Mode Start Mode

The RR-R SP is also equipped with Start Mode for race starts. It limits the engine RPMs at 6,000, 7,000, 8,000 and 9,000 RPM set-points, even with a wide-open throttle, helping the rider focus on clutch release (and lights) alone. A quickshifter is also fitted as standard, with performance optimized for racing performance and reliability.

|

|

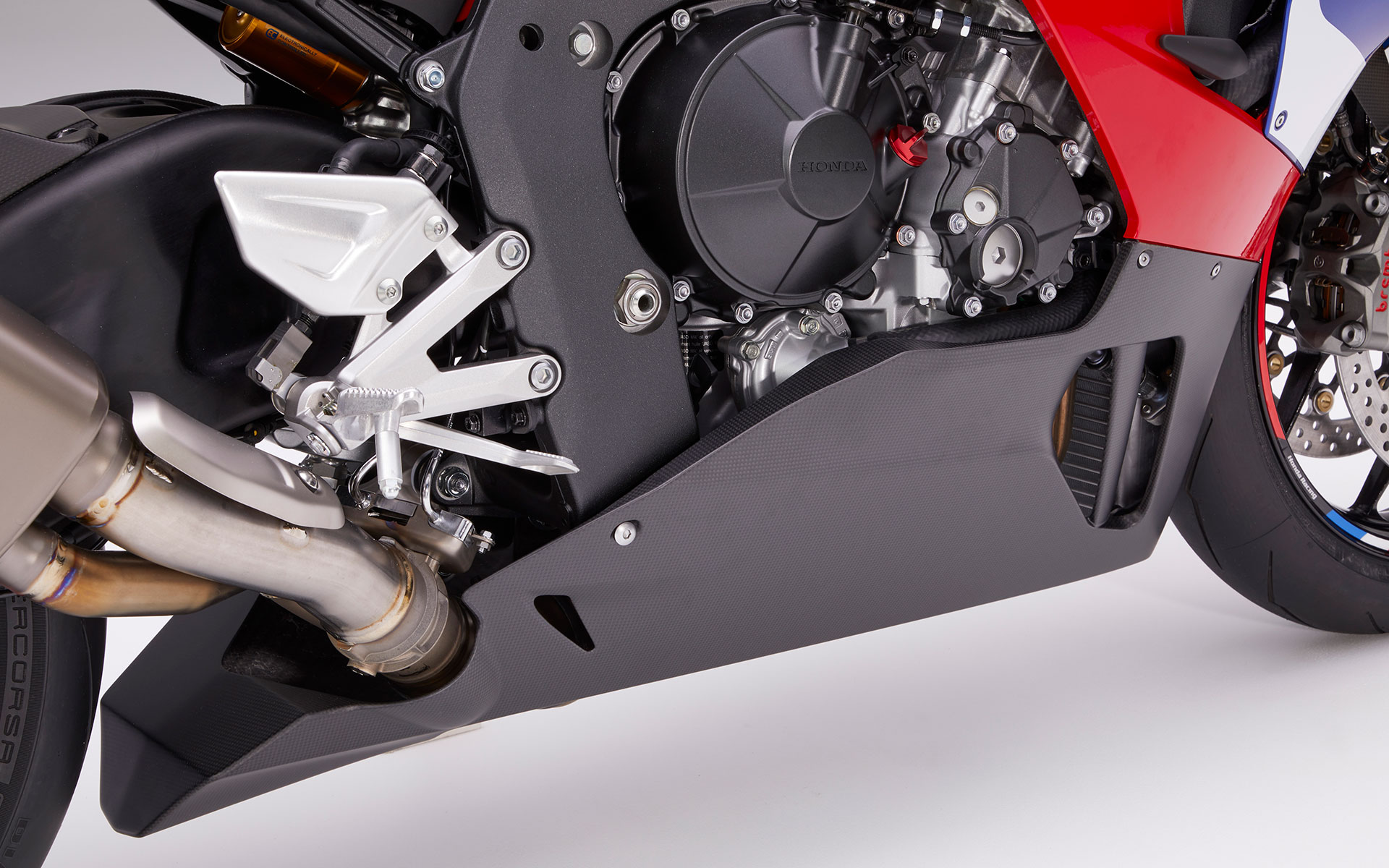

Reduced engine width Reduced engine width

To reduce width the engine is started by rotation of the clutch main shaft rather than the crankshaft. This Patent-pending, design allows for a more compact crankshaft while double use of the primary driven gear (which is smaller, with fewer teeth) to also transmit rotation from the starter motor saves space; the engine is shorter in length due to reduction in distance between the crankshaft, counter shaft and main shafts.

|